Case History: CH-07

Deliberate Actions

|

An Unknown Threat Unexpectedly Revealed Through Ultrasonic Investigation |

-

Preface

A high rise 54 story office building changes owners. When the new chief engineer takes over, he notices what seems to be abnormally high rust deposits at the package air conditioning units served by a central condenser water system. Soon after, CorrView International, LLC is hired to perform an ultrasonic investigation of the condenser water system. The building is approximately 20 years old and has been well maintained.

-

Investigation

Our investigation shows low to moderate corrosion activity of near 1-3 MPY throughout all areas tested. Like many more modern buildings, multiple futures have been installed at each floor but have never been used. For some floors we identify one set of larger 4 in. distribution lines serving the floor A/C package unit, and then 3-4 additional dead end lines ranging in size of 2 in. to 3 in. In some examples a small copper by-pass line has been installed across the dead ends in the mistaken belief that it mitigates damage caused by no water flow. Most, however, are valved off and capped. In reality, such efforts are worthless and do not slow the corrosion rate.

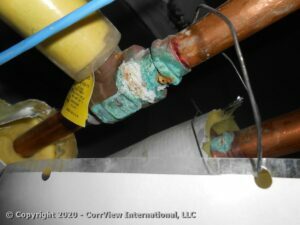

Investigation immediately discovers a significant threat at the capped future lines. In addition to higher corrosion and pitting activity, brass valves end each line and have had a noticeable galvanic impact against the steel pipe. We identify and photograph multiple locations showing rust encrustation and bluish green discoloration around the valve side of the future which defines galvanic activity. Some wall thickness measurements are not only below minimum standards, but now exist near the limit of the thread cut itself.

Investigation immediately discovers a significant threat at the capped future lines. In addition to higher corrosion and pitting activity, brass valves end each line and have had a noticeable galvanic impact against the steel pipe. We identify and photograph multiple locations showing rust encrustation and bluish green discoloration around the valve side of the future which defines galvanic activity. Some wall thickness measurements are not only below minimum standards, but now exist near the limit of the thread cut itself.

We recommend the identification and replacement of all threaded pipe throughout the entire building, and highly recommend using either dielectric fittings or heavier schedule 80 black steel pipe.

During our investigation we are advised to the existence of an above ceiling located 4 in. distribution line running the entire length of the third sub-cellar. Testing in this area identifies the most severe pitting of our entire investigation and shows that the pipe is very near failure. Thickness values in many areas are near 0.115 in. or less, and with the thread cut for 4 in. pipe at 0.105 in., very little wall thickness remains for pipe operating under a pressure of near 400 PSI.

We bring this information to the attention of the chief engineer and further warn him that while performing our testing at the very bottom of the main risers where the 4 in. distribution pipe originated, there were no isolation valves. The chief engineer expresses shock at our statement, and upon inspecting the riser pipe personally, finds that the very heavily damaged 4 in. pipe has been simply welded into the side of the main risers to the roof. Any failure of this 4 in. pipe will drain 57 floors of both risers and cooling towers into the basement of the building. With the roof level pipe to the risers originating at 24 in., substantial water exists above this 3rd level sub-cellar.

Within a few days, the chief engineer performs an emergency installation of new 4 in. isolation valves at the bottom of the condenser water system by freezing the 8 in. risers. This provides some safety margin while preparations are made to replace hundreds of feet of the 4 in. pipe routing through multiple offices. Plans are also underway to shut down the risers and replace some of the threaded pipe.

-

Conclusion

Upon cutting apart the 4 in. sub basement distribution piping, engineers find multiple lengths of 1 x 4 wood studs inserted into both supply and return lines. For whatever reason, and likely due to some form of dispute with the HVAC contractor or between employees and their firm, steamfitters deliberately inserted lengths of wood into the pipe before threading it into place. This obstruction then slowed the flow of water down to explain the long term balancing and operation problems the engineers had never been able to correct from day one.

Upon cutting apart the 4 in. sub basement distribution piping, engineers find multiple lengths of 1 x 4 wood studs inserted into both supply and return lines. For whatever reason, and likely due to some form of dispute with the HVAC contractor or between employees and their firm, steamfitters deliberately inserted lengths of wood into the pipe before threading it into place. This obstruction then slowed the flow of water down to explain the long term balancing and operation problems the engineers had never been able to correct from day one.

Slowed water flows due to the obstruction over the prior 20 years had led to the settlement of massive amounts of rust and particulates creating a severe under deposit condition resulting in the wall loss measured ultrasonically. Some lengths of 4 in. pipe fracture at their threads and separate when handled during the replacement effort.

Months later, when the dead ended futures are replaced, engineers find that many pipe sections simply snap off from the threadolets with only minor handling, requiring a re-cutting of the threads. Our final written report from ultrasonic testing had suggested this may occur, and we had recommended having thread cutting dies available in the different size pipe they were planning to replace.

© Copyright 2023 – William P. Duncan, CorrView International, LLC